Sweep’x ™ brings new possibilities for your end of line.

Sweep’x ™ opens up possibilities for handling products on a production line at high rates, in a flexible way using linear motors.

Video

Brochure

Case Study n°1

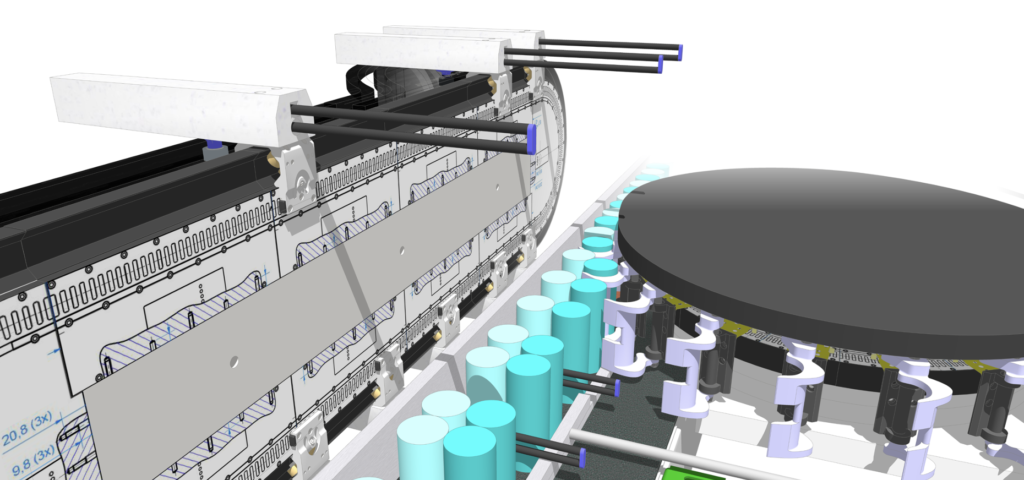

Integrated divider-grouper

- Single primary containers

- Glass, plastic or alu, cans, cups, flask, jar, etc.

- Diameter range : 50mm to 100mm

- Line speed : expected range from 5 000 up to 60 000 products/h according to product characteristics

- Outfeed configuration : from a 4x collation up to a 24x and more collation, on one or several lanes according to customer requirements

Main benefits

- Soft handling of the products

- Automatic changeover

- Servo driven latest technology and motion with friendly maintenance

- Controled pitching, configurable

- Flexible, outfeed collation from x2 up to x24 and more according to customer requirements

- Collation ideally prepared for downstream equipment (no need for products re-selection)

- Ultra compact solution (total length < 2 meters)

Case Study n°2

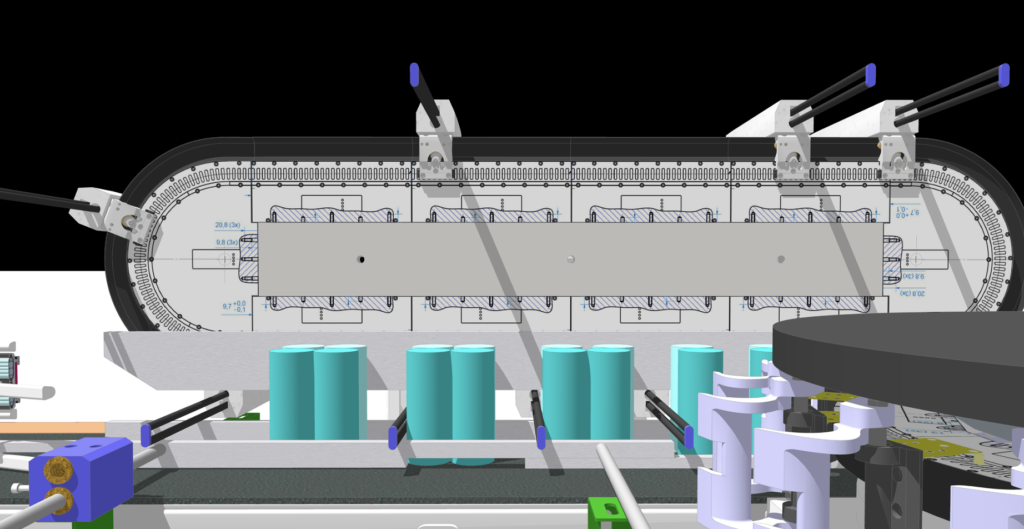

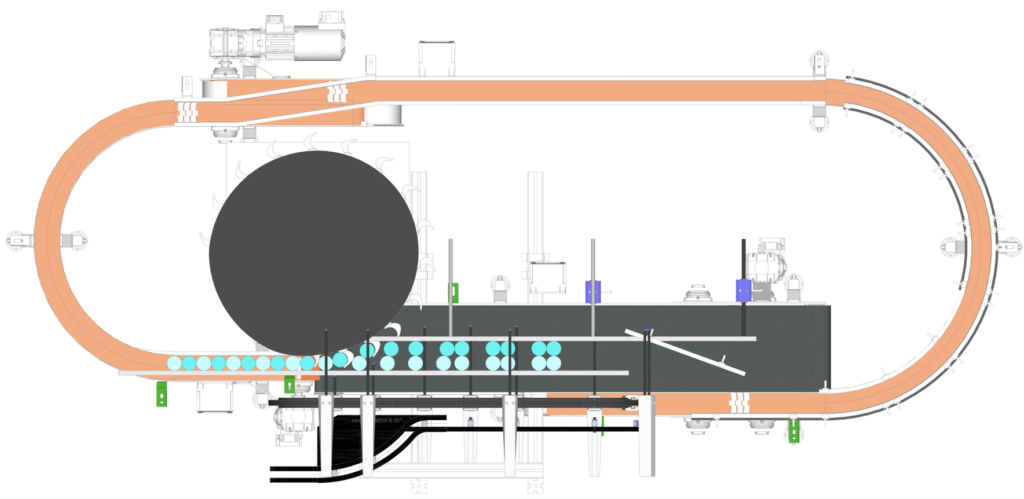

FIFO dynamic accumulator

- Single primary containers

- Glass, plastic or alu bottles, cans, cups, flask, jar, etc.

- Base dimensions range: 50mm to 100mm

- Line speed: expected range from 5 000 up to 60 000 products/h according to product characteristics

- Buffering: 1 to 5 minutes according to configuration

- Width and length: configurable, to suit buffering time and floorspace requirements

Main benefits

- Soft handling of the product, minimum contact between each other

- FIFO emptying, allowing product tracability

- Configurable (length / width) according to customer requirement

- Servo driven latest technology and motion / friendly maintenance

- Automatic changeover

- Integrated outfeed divider function as an option (products optionally clear on 2 or more lanes)